Our Environment

Circular Economy

At JBS, we are working to apply strategic, circular-economy concepts across our operations to reduce, reuse, recover, and recycle materials and energy within closed loop systems and minimize disposal and waste. Doing so not only creates new business opportunities for our company, but also disruptive solutions that support our operational continuity into the future. It is an integral component of our business model and influences the long-term decisions we make.

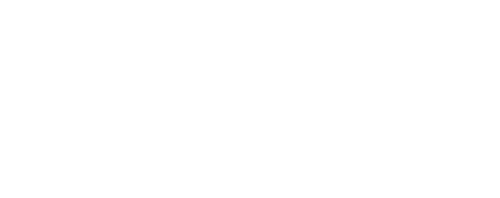

For example, rendering – the process of repurposing byproducts that would otherwise go to waste – is an important but often overlooked component of food sustainability. According to the North American Renderers Association (NARA), the meat, bone, hide, and other scrap materials that many consumers consider inedible are reclaimed and recycled into more than 8.6 million metric tons of fat, oil, and protein each year via rendering.

Responsibly diverting these materials from landfill and other disposal methods helps reduce food waste, decrease GHG emissions, and return clean water to natural waterways. In addition, many materials are responsibly repurposed into valuable new products such as sustainable fuels.

Over the last two decades, JBS has implemented a number of initiatives to sustainably transform inedible byproducts produced in our operations into biodiesel, nutraceuticals, soaps, animal feed, and more. Packaging and organic waste generated during JBS processing is also transformed into new packaging for use at JBS operations and fertilizers for sale, respectively.

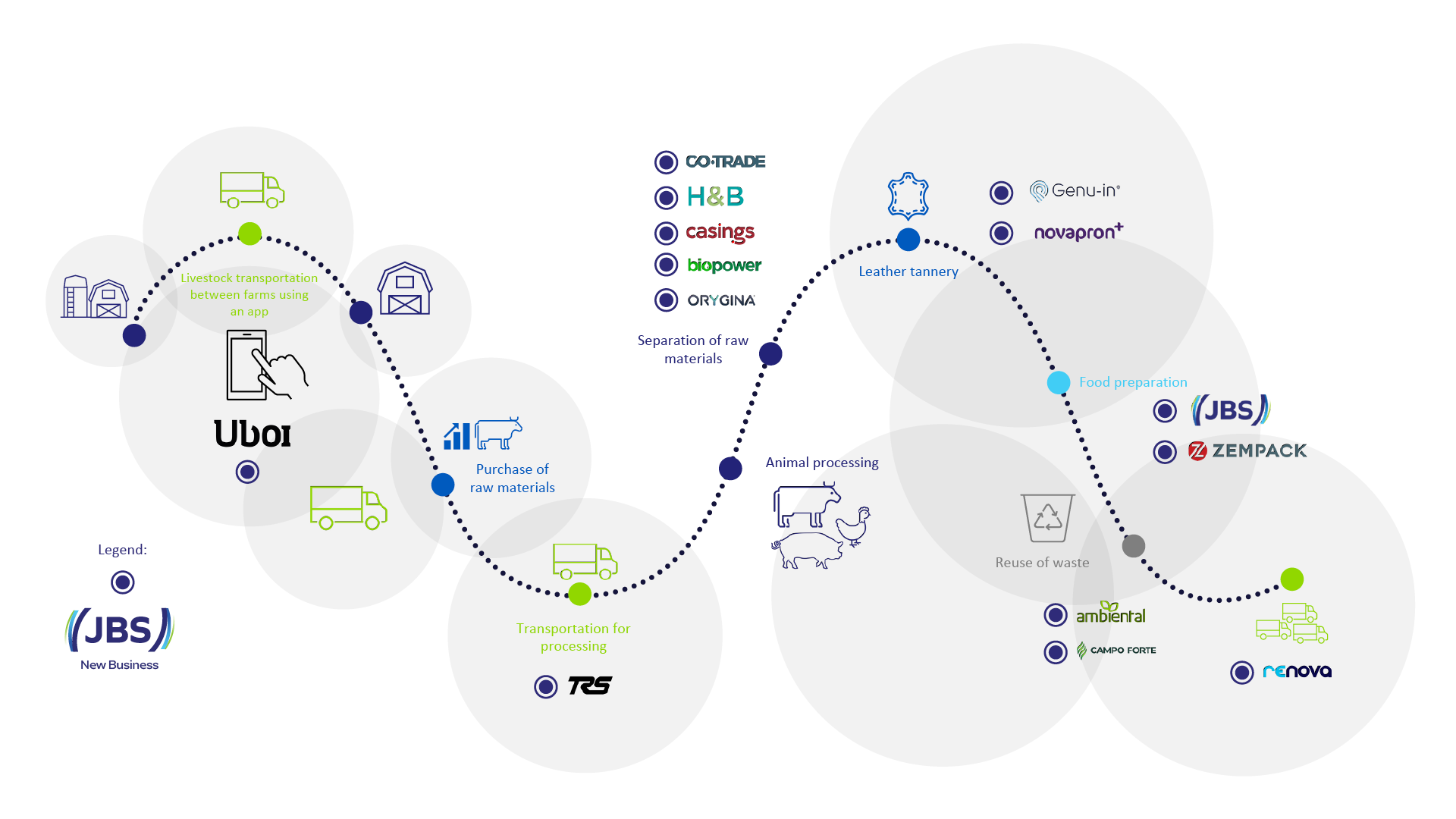

In alignment with this strategy, JBS has two business units in Brazil that are dedicated to circular economy principles: JBS Couros and JBS New Business.

JBS Couros

With a global presence and operations across four continents, JBS Couros produces more than 55,800 pieces of leather per day of leather for sale at wet blue, wet white, semi-finished, and finished stages of hide processing. The company primarily operates in three major markets: automotive, furniture, and footwear. It also provides processing solutions that incorporate innovation, logistics, and value chain control to help improve product quality and consistency, as well as ergonomics and industrial automation.

By transforming animal hides into leather through tanning, we create a material with various useful applications. In this regard, we also prioritize environmental impact and waste reduction, as any unused raw material would otherwise need to be incinerated or disposed of in landfills.

JBS New Business

JBS New Business Closed-loop systems for recycling waste can play an important role in the long-term viability of operations. JBS New Business is a group of companies that create value out of traditional waste streams, converting byproducts and waste from animal protein processing into value-added products, such as biodiesel, collagen, natural casings, fertilizers, nutraceuticals, personal care products, and more that are sold in Brazil and 50 other countries. JBS New Business is advancing innovation, efficiency, and sustainable practices in line with circular economy principles.

Our Solutions

Hygiene and Cleaning:

As a leading producer of soaps made from beef tallow and other raw materials for the B2B segment in Brazil, the H&B (Higiene e Beleza) business has a production capacity of more than 1 billion units per year.

Health:

Our Genu-in business uses cattle hides to produce high-performance collagen peptides for nutraceutical markets and gelatins for food and pharmaceutical industries. Our Orygina business also provides products to the pharmaceutical industry, research centers, and other technology-focused and scientific markets.

Environmental:

Ambiental develops products and solutions from solid industrial waste and manages and treats non-recyclable items, tracking their lifecycle and ensuring they are properly disposed.

Biopower is a Brazilian leader in transforming organic waste generated by cattle processing, such as beef tallow, and used cooking oil into biodiesel. Annually, it produces approximately 550 million liters of clean fuel and avoids approximately 910 thousand metric tons of GHG emissions through RenovaBio Certification.

Food:

Our Novapron business converts bovine collagen into high-functioning protein solutions that improve the texture, yield, and stability of processed foods. It also develops innovative solutions in ingredients for various sectors of the food industry. Casings is also a global leader in producing animal-based casings for salamis, sausages, and more.

Agribusiness:

Our Campo Forte business produces a complete line of fertilizers from organic waste, using circular economy-based efficiencies and practices.

Packaging:

As a leading aerosol and food 4.0 metallic packaging company in Brazil, Zempack has three production facilities with a combined capacity to produce more than 1 billion packages per year. The operation supports Prolata, a Brazilian non-profit association dedicated to reverse logistics, toward a shared goal of promoting circular economy and sustainability throughout our value chain.

Commodities:

Co-Trade specializes in the sale more than 950 thousand metric tons of oils, fats, and chemical products annually, serving several different market segments through strategically located tankage facilities in the primary ports of Brazil.

Transportation:

Our Brazilian carrier, TRS, has its own fleet of trucks to help ensure the safe transport of live animals, leather, dry cargo, containers and other goods. The TRS fleet is renewed every three years through Renova, our business dedicated to fleet renewal.

In addition, our carrier also has Uboi, which is a service offered via application by JBS for transporting live animals. It has trained drivers, a 24-hour monitoring center, and relevant animal welfare certifications (see Our Animals for more information).

Aiming to diversify our fleet, we have No Carbon, our fleet of electric trucks in Brazil, which specializes in the transport of frozen and refrigerated products.

Reverse Logistics

JBS promotes recycling and repurposing post-consumer packaging waste materials back in our supply chain as a means of reducing the impact of landfills and raw material consumption. In 2023, JBS Brazil supported reverse logistics projects in alignment with the National Solid Waste Policy, established by Law No. 12,305 of August 2, 2010, through partnerships with the Prolata Program, Pragma’s Recupera Program, and Eureciclo.

In addition, other projects developed in collaboration with Ambiental to improve the segregation of recyclable materials are currently ongoing.

Please visit our website to learn more about Ambiental.