Our Environment

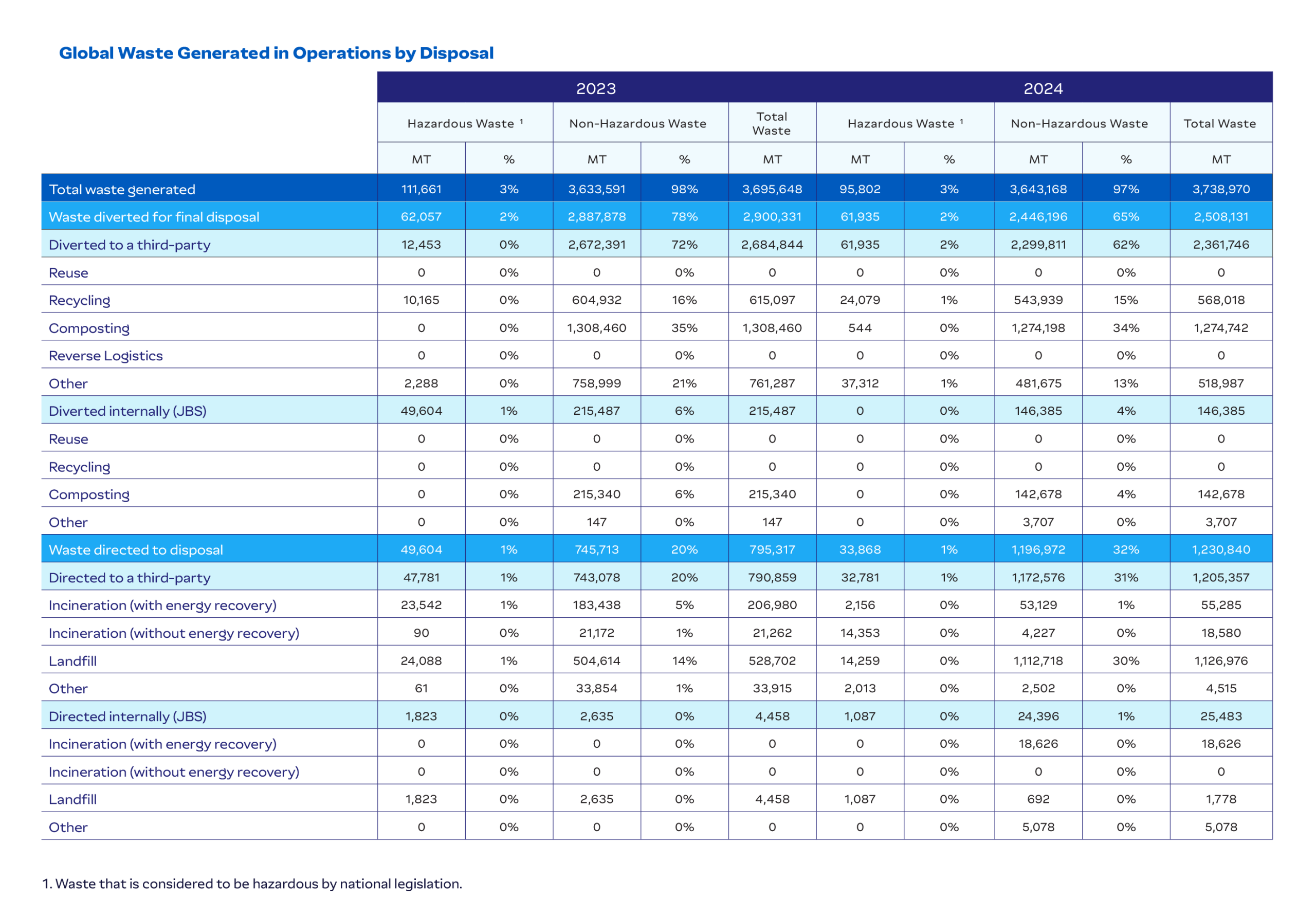

Waste Management

(GRI 2-23, 3-3, 306-1, 306-2, 306-3, 306-4, 306-5)

Guided by our Global Packaging and Recycling Policy, we aim to minimize waste generation, maximize reuse and recycling, and maintain compliance with local, state, and federal regulations across all global business units. Our approach reflects the principles of circular economy and resource efficiency.

JBS adheres to comprehensive legal frameworks and industry standards that guide our waste management practices globally.

Rigamonti: Follows local Italian law and ISO 14001 operating instructions for proper waste management.

Across all regions, JBS’s environmental policies prioritize actions to reduce, reuse, and recycle resources, fostering a culture of innovation and accountability while maintaining strict adherence to applicable regulations. Materials that can be recycled are separated and sent to recycling companies, and where possible, organic waste is transformed into alternative products such as compost. Nonrecyclable, hazardous, and harmful waste is separated for appropriate final disposal.

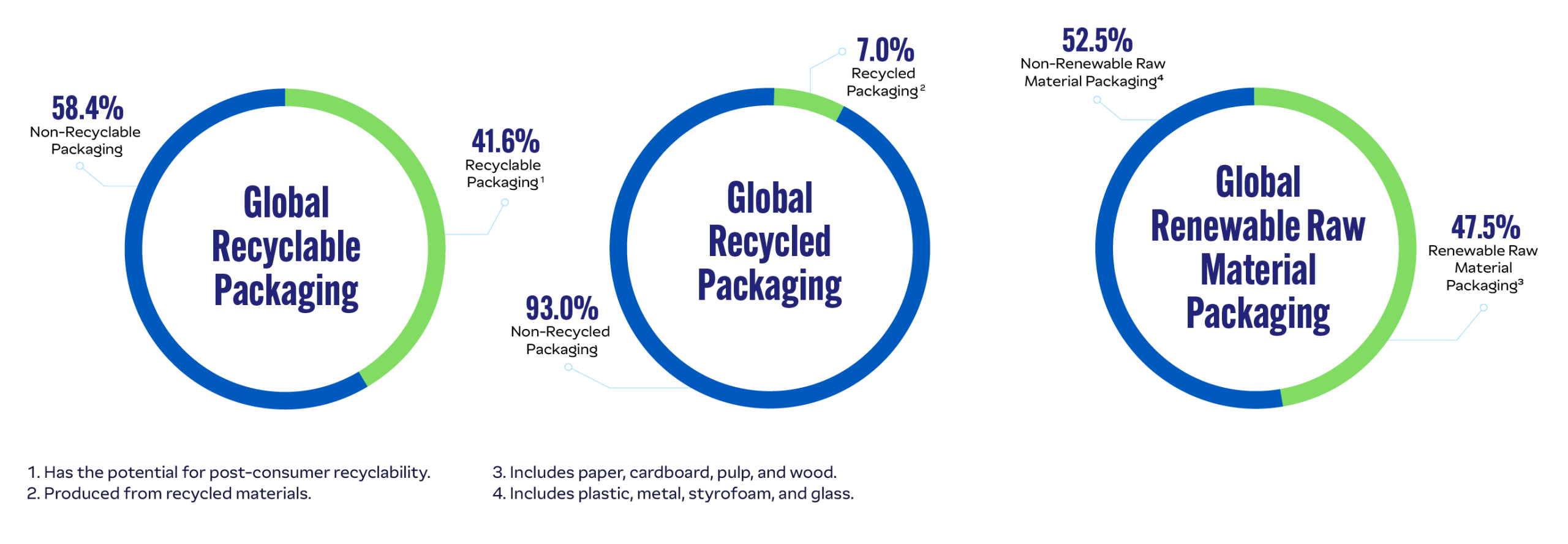

Packaging

(GRI 3-3, GRI 301-1, 301-2)

While packaging plays a vital role in protecting food quality and safety, traditional materials like single-use plastics can contribute to waste and pollution. By reimagining packaging design, incorporating recycled and renewable materials, and reducing reliance on virgin resources, JBS aspires to advance circular economy principles and minimizing its environmental footprint. We aim to increase our offerings of functional, sustainable packaging solutions that align with our customers’ preferences and broader environmental goals.

Innovative Packaging Materials

(GRI 301-1, 301-2)

JBS’s Research and Development (R&D) teams work to reduce and optimize the use of primary (direct contact with food), secondary, and tertiary packaging, minimizing customer and consumer-generated waste while maintaining product integrity and operational efficiency.

JBS manages packaging through tailored strategies, advanced tools, and collaborative efforts across its business units, with each unit employing a unique approach to address its specific operational needs while prioritizing sustainability, efficiency, and compliance with regional, national, and global standards.

In 2024, JBS made strides in responsible packaging use in multiple operations. Primo Foods focused on packaging reduction and recyclability, successfully downgauging 12% of soft and rigid plastic bottom films, resulting in a reduction of approximately 200 metric tons of plastic per year. Furthermore, Primo Foods transitioned the majority of rigid plastic to mono PET (Polyethylene terephthalate) and began transitioning soft plastics to recycle-ready polyolefins (PE and PP), achieving 92% recycle-ready packaging placed on the market.

Transitioning to Recyclable and Renewable Alternatives

We are actively pursuing innovative solutions to reduce our reliance on plastic and eliminate the use of Styrofoam trays across operations by transitioning from traditional plastic packaging to recyclable and renewable alternatives.